Designing and manufacturing the Compack Hanger was one of the most gratifying experiences I’ve had as a product designer. Through my work on the product, I gained a higher resolution understanding of the design process, including some valuable lessons along the way.

Step 1: Discovery

Tasks: Interviews, Trend Identification, Specification Documentation

Tasked with solving a problem for the college student market by our Product Design professor, Karl T. Urlich, many of us scrambled to examine our own lives for pain points. From tangled headphones to limited dorm space, day-to-day complaints spanned the gamut.

Chatting with my team, a pressing problem we realized we had was that of what to do with all our clothes hangers during move-in and move-out. We realized many students throw out what they can’t pack or store and buy new ones the next year. What a waste and hassle!

Step 2: Design

Tasks: Free Ideation, Sketches

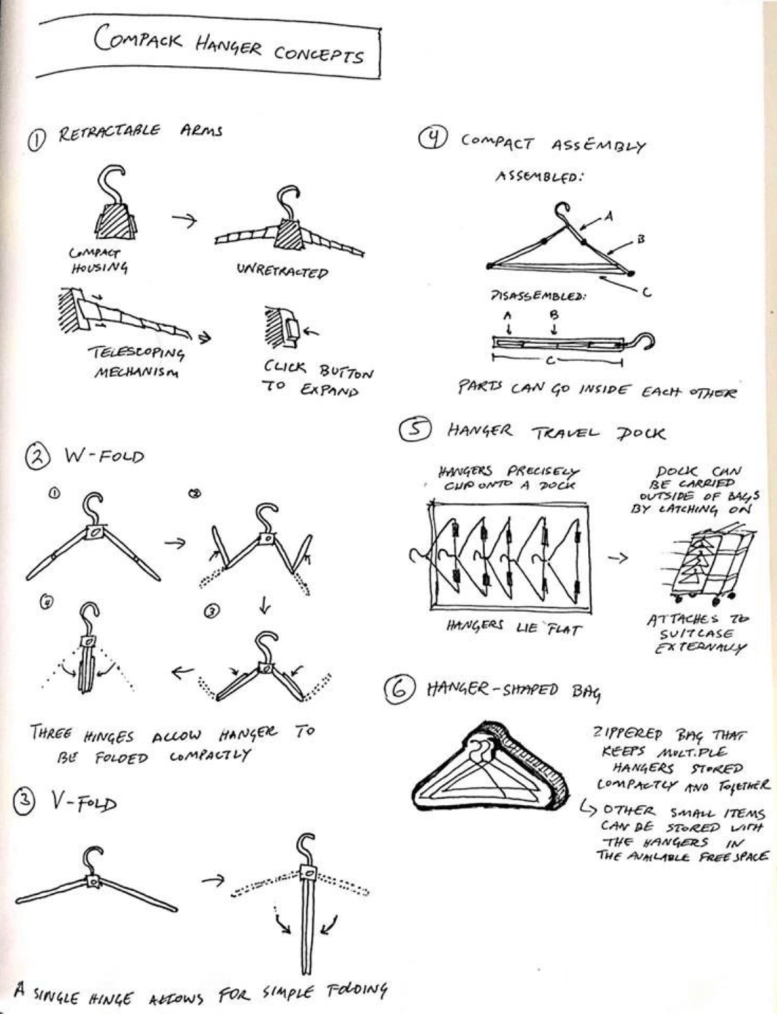

We started coming up with ways hangers could be made minimalistic, foldable, collapsable, retractable, even…spring-loaded? Defining and sharing one idea would lead to more. This part of the process is always fun; our creative problem solving minds ran free.

Step 3: Refine

Tasks: Down Select/Converge Concepts, CAD

Of course, creativity must be tethered to reality: design constraints, a problem to be solved, a job that needs doing. To that end, we honed in on our three most clever, practical ideas, and polled the class.

Step 4: Implement

Tasks: Prototype Manufacturing, Surveys

The idea that won out in the end was significantly different from the three we initially proposed. As designers, we thought we had it all figured out to some extent, and whether we went forward and manufactured A, B, or C was simply up to our classmates’ preference.

Hah, if only.

We received enlightening questions and feedback from our classmates, the stakeholders of our design. For example: would the hanger be able to bear the load of a heavy jacket? How much would they cost? Would they last? Plus, being a team of unfashionble engi-nerds, we would never have thought to add notches for dress straps, as was pointed out by many of our dress-owning classmates.

Surveys responses were a gift.

Step 5: Verify

Tasks: Improvement, Testing, Costing, Manufacturing

After finalizing our design, we proceeded to make improvements based on the feedback and hone in on the functionality and cost.

Between various manufacturing methods for plastics, a combination of laser cutting and 3D turned out to be the most cost effective and accessible for us. I came to understand “design for manufacturability” as a practice for the first time, realizing the best idea won’t go anywhere if it can’t be manufactured or is prohibitively expensive.

After several weeks of iterative design, feedback gathering, surveys, and time in the lab, we soon had a final product in our hands.

Step 6: Execute

Tasks: Photography, Launch Marketing, Creative Branding

The annual Design Fair came around at the end of the year and we were ready. Poised to present “the iPhone of hangers,” we set up the booth you see below. Each of the 200 or so attendees—students, professors, the public—were given 3 tickets with which they were asked to vote for the their favorite products, of 40 presenters.

At the end of it, we learned we had been voted on the most, winning title of best design, taking into consideration the form, functionality, and cost of our product. Together, our iterative design effort, surveys, and marketing presentation coalesced into a successful product.

Conclusions

Looking back, I picked up a number of valuable lessons from Compack. They seem obvious now, but were gained from experience:

Good design is iterative and shaped by stakeholders.

Surveys and polls can elucidate new, needed product features.

The available manufacturing methods can shape the design—both its form and its cost.

Presentation, branding, and marketing are as important to the product’s success as the design itself.

A team with a well-rounded skillset is a joy to work with.